Posts

Showing posts from 2014

Posted by

Elmer Nahum

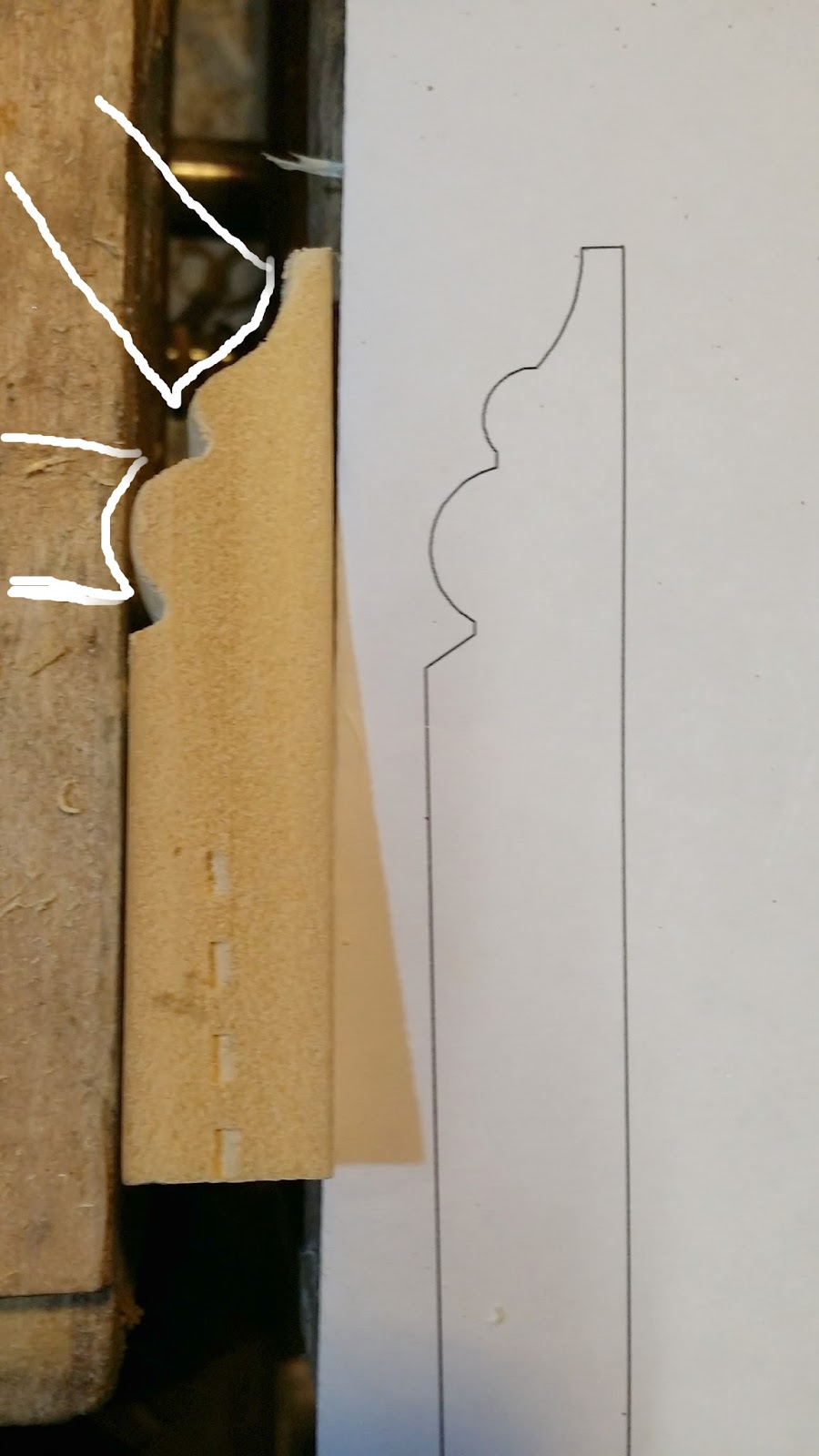

Cellular PVC vs. The Stanley 55 Plane

- Get link

- X

- Other Apps

Posted by

Elmer Nahum

Modified Fence For The Stanley 55 Plane

- Get link

- X

- Other Apps

Posted by

Elmer Nahum

The Stanley 55 Plane: Power Point

- Get link

- X

- Other Apps

Posted by

Elmer Nahum

Expanding The Stanley 55's Capabilities With Angled Fences

- Get link

- X

- Other Apps

Posted by

Elmer Nahum

Sliding Dovetails With The Stanley 55 "Saw Plane"

- Get link

- X

- Other Apps

Posted by

Elmer Nahum

Another Meaning of Hybrid Woodworking: The Stanley 55 "Saw Plane"?

- Get link

- X

- Other Apps