Cellular PVC vs. The Stanley 55 Plane

Cellular PVC is a synthetic wood-like product for outdoor applications that is rot resistant and can be milled similar to wood. There are several different manufacturers. The manufacturer claims that the product can be milled, cut, routed and finished with standard woodworking tools.

I needed to make an exact copy of some base trim moulding for a newel post. Even H. G. Wells probably never envisioned that the Stanley 55, a contemporaneous steam-punk style moulding plane of his era, could be used a century later to mill mouldings on artificial wood.

CELLULAR PVC

Pros:

Cons:

I needed to make an exact copy of some base trim moulding for a newel post. Even H. G. Wells probably never envisioned that the Stanley 55, a contemporaneous steam-punk style moulding plane of his era, could be used a century later to mill mouldings on artificial wood.

CELLULAR PVC

Pros:

- No knots

- No worry for grain direction...there is none

- No rot

Cons:

- Plastic dust (I wore a respirator even when working this material by hand)

- Difficult to make paper thin passes with the plane, although the thicker shavings left a fairly smooth surface

- Thinner shavings sometimes don't pop off the wood. If you generate enough heat, that residual shaving can meld itself back on the piece when working with the moulding plane.

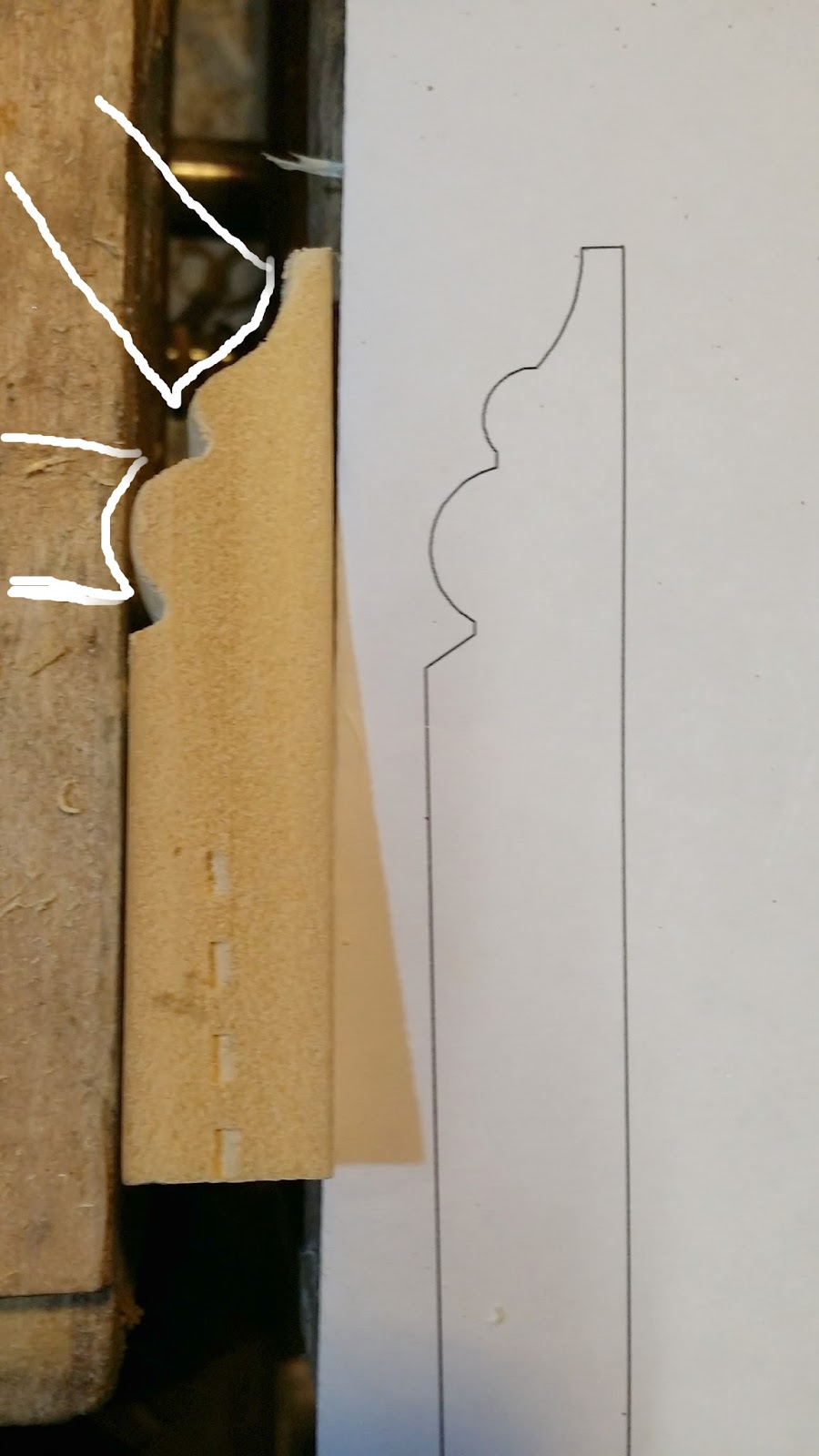

To make the moulding, two different cutters for the 55 plane were combined. But, the profiles did not quite match. The plan was to match as much of the pattern as possible and finish up with a scratch stock. The profile was traced on both ends of the board. The first cut was made with the board vertical in the vise, working from the edge of the board, with the reverse ogee cutter #84 tilted to about 30° using both fences as described in a prior post. This produced the upper cove and upper half of the upper bead. The stock was then worked from the face for the lower bead with the hollow cutter #44. Finally, the scratch stock finished the profile.

|

| Two different cutters were used. The top cutter was worked from the edge using both fences. This gave a crisp clean cut. The lower bead was worked from the face with the board clamped face side up. |

Take thin passes for nice shavings

|

| Second bead |

|

| Working the board with a scratch stock |

Overall, the cellular PVC was workable with hand planes and can provide surprisingly satisfactory results, especially considering this will be for outdoor use. The product I used for the final trim was from Azek. I had another leftover piece that was smooth on all four sides from another manufacturer (Veranda brand?) for the initial trial cut that has a wood like color, rather than the white color through and through , that seemed to give a cleaner result, but I could not find this material nearby.

Comments

Post a Comment